Magnet Free-Fall Experiment

Mark 3

The Mark 3 magnet free-fall object consists of the 3D printed plastic shell, the XPS foam encasement layers, the Arduino Nano 33 BLE Rev2, PowerBoost 500 Basic, a 3.7V Lipo 250mAh Battery, and one K&J Magnetics RY04X0 magnet.

Results

- Grade: F

-

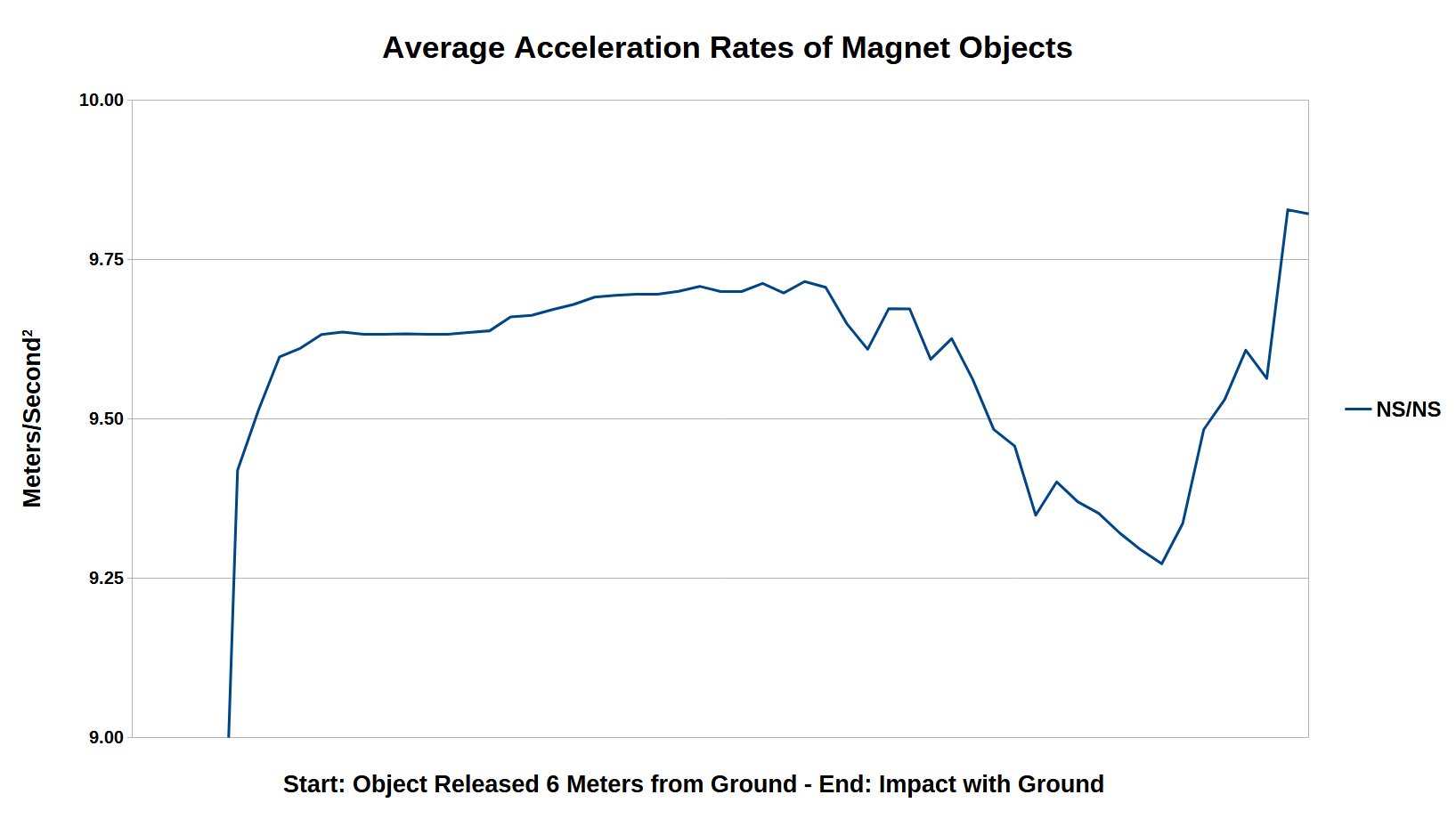

- Max Acceleration: 11.2528 m/s2

- Average Acceleration: 9.8217 m/s2

- Magnet: N42, 2″ OD, 1″ thick

- Height: 7 meters

- IMU: BMI270

- Drop Method: Hand

- Replication Warranted: No

Overview

This experiment was conducted using one 2″ OD, 1/4″ ID, 1″ thick, N42 neodymium magnet in the hopes that the free-fall object would fall more vertically in the direction of north pole to south pole of the magnet. While that did take place, the magnetic field was substantially reduced compared to Mark 1 and Mark 2 experiments.

The Mark 3 plastic shell and foam encasement was likely not being fully enveloped by the field of emitted by the magnet. As a result inertial mass reduction only occurred partially on the free-fall object.

The Arduino’s built in IMU also seemed to be having problems. Looking at the data, the Z-axis would often have a negative sign where it seems it should have a positive sign.

In future experiments I will be using the Adafruit BNO055 IMU which is reportedly very accurate and it has its own self-calibration routine.